City Limits takes a multimedia look at how food waste is repurposed at the Department of Sanitation’s 33-acre composting facility in the Fresh Kills section of Staten Island. The site is part of New York City’s effort to operate “the nation’s largest composting program” and limit the climate impacts of its waste sector, which accounts for 4 percent of citywide emissions.

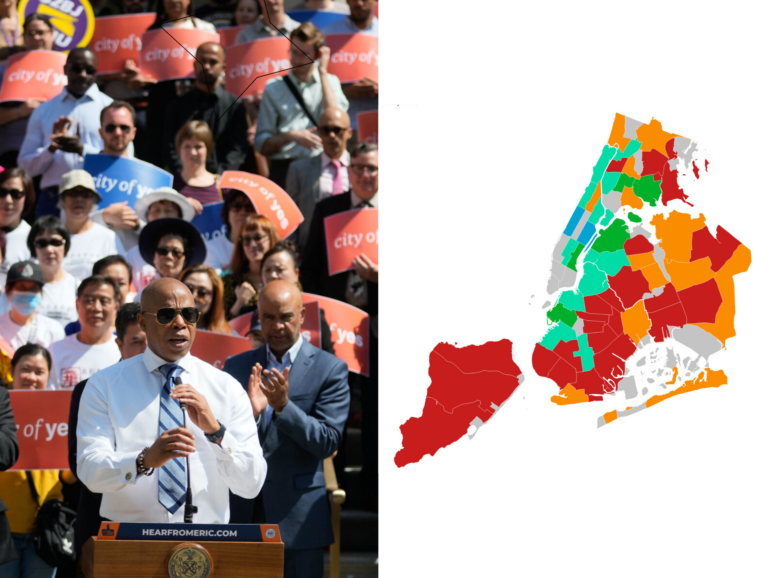

Above: Ian Twine, DSNY’s deputy director of composting, explains the process for breaking down food waste at the agency’s 33-acre facility on Staten Island. Photos and audio by Adi Talwar.

Every year, New York City residents produce more than 14 million tons of trash. About a third of that is organic waste—yard debris and food scraps that, left to rot in landfills, produce methane that contributes to climate change.

Several efforts are underway to address the environmental impact of the city’s waste sector, which accounts for 4 percent of citywide emissions. Residents can now drop off food scraps at hundreds of sites across the five boroughs, including sidewalk “Smart Bins” accessible 24 hours a day through an app.

Adi Talwar

Upper left: Jack Bernatovicz using a “Smart Bin” at the corner of 34th Avenue and 24th Street in Queens. Right: DSNY employees Gavin Cleghorn and Justin Somoano collecting from the bins.

Adi Talwar

DSNY employee Gavin Cleghorn in a sanitation truck in Queens during his evening route to pick up compostable waste from “Smart Bins.”

Curbside composting collection, which initially got off to a rocky re-start after a pandemic hiatus, will expand to every borough by the end of next year, having diverted more than 2.7 million pounds of organic waste from Queens alone during a pilot program last fall. The city is also proposing a rule that would require residents to separate their yard waste from recycling so it can be composted instead.

Some of that organic waste might get processed into gas for use as an energy source. Some will end up in Fresh Kills, Staten Island, where the city’s Department of Sanitation (DSNY) has a 33-acre facility devoted to composting food scraps dropped off by residents and collected from school cafeterias, as well as debris collected by landscaping companies.

City Limits took a tour of the site earlier this year, in which Ian Twine, DSNY’s deputy director of composting, explained the months-long process that breaks down organics into nutrient-rich material. That final product, which resembles a deep brown soil, then gets packed into bags and dubbed “Big Apple Compost,” which the city sells or hands out at community events.

Adi Talwar

Green waste being dumped from a 64 gallon toter at the Staten Island composting facility.

Adi Talwar

Green waste in plastic bags is processed by machine called the Tiger, which separates food scraps from light contaminants like plastic bags.The whole process takes between six to eight months, though an Aerated Static Pile (ASP) system being installed at the Staten Island facility will significantly speed things up, according to Twine.

Once that’s completed, composting will take just three to four months from start to finish, and allow them to boost site capacity from the 1,500 tons of food waste they’re currently permitted to process to 30,000 tons. “So a huge jump,” Twine said.

Adi Talwar

Green organic waste is mixed with water in a machine called the Tiger which grinds the green waste to an oatmeal consistency.

Adi Talwar

A worker washes 64 gallon toters that are used for transporting food waste

Adi Talwar

Part of the new 16-bay Aerated Static Pile composting system being constructed at DSNY’s Staten Island facility. Each bay will have temperature monitoring probes and aeration lines. The new system will half the time required for composting.

Adi Talwar

Each bay will have temperature monitoring probes and aeration lines.

Food waste dropped off at the site gets put into a machine called the Tiger, which separates the heavier organic components from lighter contaminants like plastic bags. It’s then mixed with water and the machine grinds the scraps down until they take on “an oatmeal kind of consistency.”

“It then goes into a dump truck that has wood chips in it to absorb any excess liquid so it doesn’t leak anywhere,” Twine explained. “Then once that truck is full, it’s brought over to a specific windrow drop there and then is processed with a machine we call the Scarab, which is literally a broad machine with a rolling pin on the bottom that chops up the material.”

Adi Talwar

The Scarab machine’s rolling cutter that turns and grinds compostable material in windrows.

Adi Talwar

The Scarab machine that turns and grinds compostable material in windrows.

In addition to food scraps, the Staten Island facility also composts yard waste collected by city agencies like the Parks Department and from landscaping companies. The facility is also permitted to process up to 70,000 cubic yards of “woody debris.”

“Which is really targeted for the times when we become a site for any large scale wood event, like a hurricane, that creates a lot of wood waste,” Twine said. “During Sandy we became a city dumping zone for chipping and removal of all those trees.”

Above: Ian Twine, DSNY’s deputy director of composting, explains how the site breaks down yard waste. Photos and audio by Adi Talwar.

Adi Talwar

Yard waste is processed by two types of grinders, a slow speed grinder and a horizontal grinder. Once the yard waste is ground up, it sits in a pile for a few months, it gets rotated and finally ends up in a windrow where it finishes it’s composting process.Both food and yard waste is eventually moved into long horizontal rows called windrows, which speeds up the composting process, where it sits for a month before being moved into “curing piles” to sit for another month. As worms, bacteria and fungi break down the organic waste, the material turns darker in color.

The piles heat up to around 130 degrees Fahrenheit inside due to the natural composting process. “It’s warmer than the surrounding air so you get this really wonderful steam pile—it’s really dramatic when it’s really cold outside,” Twine said.

Adi Talwar

Windrows of composting organic waste. As worms, bacteria and fungi break down the organic waste to compost the material turns darker in color.

Adi Talwar

Water vapor rising from composting organic material as it is moved. The composting piles heat up to around 130 Degrees Fahrenheit due to the natural composting process.

Adi Talwar

Final screening of compost material before it becomes usable compost.

Adi Talwar

From there, a machine stuffs the compost into 40 pound bags with the Big Apple Compost label, which boasts that the product is “Made From 100% NYC Organics.”

“One pallet is 60 bags, of 40-pound bags. We can do a pallet in four minutes,” said Twine. “It’s a fun machine to watch.”

Adi Talwar

The Compost bagging machine at can bag up 60 bags of compost in four minutes.

Adi Talwar

Bagging Supervisor Zack Morrell moving bagged compost. Morrell is an employee of Denali Water Solutions, which has the contract for running DSNY’s Fresh Kills composting facility.

Adi Talwar

The final product: 40 pound bags of Big Apple Compost, which gets sold to landscapers and given out to residents at community events.